TURNAROUND DIAMONDS

Description

![]() is a single point, high precision, top quality dressing diamond giving maximum straightness, great surface finish and maintaining fine tolerances. Designed with a thread (for easy mounting and dismounting) for use with the special extractor. Numbered 1-2-3-4 for easy identification when the diamond is turned around. No need to reset the diamond zero and workpiece zero positions after changing to new positions. Available with different angles and radius (the first 2 figures are the angle followed by the radius).

is a single point, high precision, top quality dressing diamond giving maximum straightness, great surface finish and maintaining fine tolerances. Designed with a thread (for easy mounting and dismounting) for use with the special extractor. Numbered 1-2-3-4 for easy identification when the diamond is turned around. No need to reset the diamond zero and workpiece zero positions after changing to new positions. Available with different angles and radius (the first 2 figures are the angle followed by the radius).

Available: TA 7050, 7030 BMN, 7025, 6530 BMNL, 6025.

![]() is a multiple point general use, high precision dressing diamond (sometimes called fliese). They are produced in 10mm height to reduce straightness problems often found when using angle approach wheels. There are 6 to 7 selected high quality diamonds in a row for a depth of 10mm or 15mm. Ideal if used with an in process gauge. Very effective for roughing out new wheels or wheel shapes as increments 0.1mm to 0.2mm per dressing stroke may be used. Easy to mount and dismantle (using the special extractor) thanks to the thread on the shank.

is a multiple point general use, high precision dressing diamond (sometimes called fliese). They are produced in 10mm height to reduce straightness problems often found when using angle approach wheels. There are 6 to 7 selected high quality diamonds in a row for a depth of 10mm or 15mm. Ideal if used with an in process gauge. Very effective for roughing out new wheels or wheel shapes as increments 0.1mm to 0.2mm per dressing stroke may be used. Easy to mount and dismantle (using the special extractor) thanks to the thread on the shank.

PCD triangle may be used for small profiles or general dressing. There are 3 edges and come with the following radius in mm 0.0mm – 0.125mm – 0.250mm – 0.50mm

PCD round may be used to profile convex and concave wheels using only 1 diamond. Eliminates the problem of having to use 2 diamonds, then trying to match the shape in width and depth and compensate for different diamond wear.

PCD holder needed to fit the pcd inserts (triangle or round). Comes with a thread on the shank (to fit the special extractor) for quick and easy mounting and dismounting.

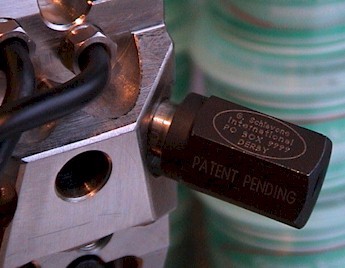

Diamond holder designed and developed to give better efficiency when dressing. It’s the 1st holder on the market that will fit most Studer cnc machines i.e. S20, S21, S30 Lean Pro, S31, S36, S40 etc. Has a drag angle of 10 degrees to enhance better diamond efficiency and surface finish. Up to 4 mini coolant outlet tubes may be fitted giving constant flow on the diamond. Designed for external dressing but may be used also for internal dressing on some Studer models and come in Nickel or Black.

Table base mounted diamond holder designed to give the up most flexibility. Fits most Studer cnc machines i.e. S20, S21, S30 Lean Pro, S31, S36, S40 etc. Can be rotated =/- 20 degrees for better positioning of the diamond. Robust and sturdy and can be used for external or internal applications. Can be fitted with 2-diamond holder’s external and internal (see Diamond holder above).

Alignment test bars for testing workhead and tailstock alignment. 4 sizes available Morse cone 5 – 4 – 3 – 2.

Centres High precision carbide centres with calibrated diameter (may also be used for simple alignment checks only). Thread for easy extraction. Available with Morse cone 3.

Relaps of the ![]() diamonds are available should you have the need.

diamonds are available should you have the need.